The Molded Interconnect Device (MID) Market is revolutionizing the electronics manufacturing landscape by enabling 3D circuit integration into molded thermoplastic components. By merging mechanical and electronic functionalities into a single compact structure, MID technology offers significant advantages in terms of miniaturization, cost-efficiency, and design flexibility for high-performance electronic devices.

Market Overview

MIDs are used extensively in the automotive, consumer electronics, healthcare, and telecommunications industries for their lightweight, space-saving, and high-reliability characteristics. The global demand for miniaturized and multifunctional devices is accelerating the adoption of MIDs across multiple sectors.

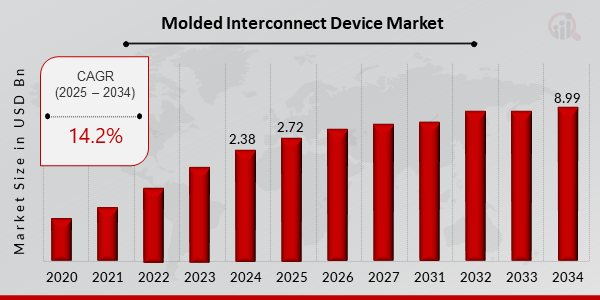

According to Market Research Future, the molded interconnect device market is witnessing strong growth, driven by the rising adoption of laser direct structuring (LDS) technology, advancements in additive manufacturing, and growing demand for wearable devices, smart sensors, and next-gen automotive interiors.

Market Segmentation

By Process Type:

-

Laser Direct Structuring (LDS)

-

Two-Shot Molding

-

Film Technique

By Product Type:

-

Antennas & Connectivity Modules

-

Sensor Components

-

Lighting Modules

By Industry:

-

Automotive

-

Consumer Electronics

-

Medical

-

Industrial

-

Telecommunication

By Region:

-

North America

-

Europe

-

Asia-Pacific

-

Rest of the World

Asia-Pacific leads the MID market due to the presence of major electronics manufacturers in China, Japan, and South Korea. Europe follows closely, especially in automotive and medical device integration.

Key Market Trends

-

Shift Toward Miniaturized Designs: Demand for smaller, high-functionality devices fuels MID adoption in mobile phones, smartwatches, and medical implants.

-

Automotive Digitalization: Increasing use of MIDs in car infotainment systems, sensors, and controls to reduce wiring complexity and weight.

-

Sustainability Goals: MIDs contribute to eco-friendly manufacturing by reducing material use and simplifying recycling.

-

Advancements in LDS Technology: LDS has become the most widely adopted process in MID manufacturing due to precision and scalability.

Key Players

Notable companies shaping the MID market landscape include:

-

Molex, LLC

-

TE Connectivity

-

LPKF Laser & Electronics

-

MacDermid Alpha Electronics Solutions

-

RTP Company

-

SelectConnect Technologies

-

DSM Engineering Materials

These players focus on R&D, strategic partnerships, and innovation in LDS-based and two-shot molding technologies to stay competitive.