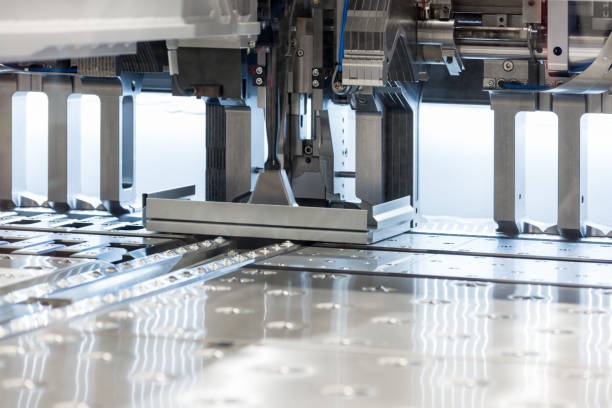

Sectors like automotive and aerospace operate in domains where precision is critical. Safety is a necessity, whether it’s a specialized section of an aircraft or a high-performance part of an electric vehicle. Every component needs to be crafted to fit and function with absolute precision. This is where flexibility stampings come in. Metal stamping components are crafted to meet industry standards and are best suited for parts that demand flexibility and strict tolerances.

Attaining precision requires whatever the design demands is not straightforward. It requires smart engineering, advanced technology, and rigorously enforced quality control. Here is how high-precision metal parts are being manufactured in the modern era.

Tight tolerances pertain to a heightened margin of error, which is restricted to gaps around, a few microns. Thus, optimal precision during metal stamping is creating components that achieves a defined design without critical discrepancies. In simpler terms, metal parts will be seamless without gaps and will deliver functionality.

Functional reliability is determined by appropriate fitting, where functionality refers to metal components working and achieving what they are made for.

In engines or electrical assemblies, slight gaps can lead to complete system failure.

Consistency in Performance: In the aerospace industry and EVs, components must endure stress, temperature extremes, and motion.

Less Waste, Less Rework: Precision cuts down on defects, meaning fewer parts need to be scrapped or sent for rework.

Regulatory Compliance: Aerospace and defense industries have strict compliance regulations which require the highest accuracy.

Strategies Responsible for Precision

- Die Design Optimization

Die design directly impacts the quality of stamped parts. To anticipate material challenges and optimize die geometry, manufacturers apply simulation tools such as Finite Element Analysis (FEA). Precision Stampings and longevity are critical, so high-grade tool steels or carbides are used.

- Electric Presses

Servo-driven presses offer distinct advantages over mechanical ones. They can control stroke, pressure, and speed which increases precision and the maintenance of dimensional consistency even in high-speed production. This makes such presses suitable for small intricate components including micro connectors or shielding parts of EVs and aerospace systems.

- Measurement Systems Operated Inline

Manufacturers detect and correct deviations in real time using laser and 3D vision technology, through real-time monitoring, and applying industry-grade sensors. This ability to adjust in realtime reduces defects significantly.

- Strict Material Control: Changes in thickness or hardness of metal materials can create critical inconsistencies. This is the reason why leading producers have close collaboration with trusted suppliers and carry out comprehensive inspections on the supplied material to determine if it is suitable.

- Precision Material Handling: Automated systems that eliminate the possibility of deformation during feeding, loading, and unloading safeguard part accuracy. Special fixtures and conveyors guarantee that the material is not stretched or bent prior to stamping.

- Tooling Maintenance: All the best dies will ultimately wear down over time. Through regular maintenance, regrinding, and wear monitoring, the tools are kept precise and sharp. There are systems that additionally integrate sensors for tool wear monitoring in real-time.

Challenges and How They’re Solved

|

Challenge |

Description |

Solution |

|

Die Wear Over Time |

This leads to dimensional drift |

Use wear-resistant materials, maintain & inspect regularly |

|

Material Variability |

Thickness or strength differences affect outcomes |

Strict incoming inspection, work with reliable suppliers |

|

Thermal Expansion |

Temperature shifts cause part distortion |

Maintain temperature-controlled environments |

|

Mechanical Drift |

Vibrations or loosening impact accuracy |

Use servo presses and apply preventive maintenance |

|

Human Setup Errors |

Wrong parameters can push parts out of spec |

Invest in training, standardised setup systems |

|

Tolerance Stack-Up |

Accumulated errors cause assembly issues |

Conduct tolerance stack-up analysis, add checks at key stages |

|

High-Mix, Low-Volume Complexity |

Frequent design shifts increase error chances |

Use flexible tooling and programmable presses |

|

Early Defect Detection |

Small errors become major if not caught early |

Use real-time scanning and monitoring systems |

Industries That Demand Precision

Automotive- Electric vehicle batteries as well as sensors and control units require precision actively within the industry.

Aerospace: In extreme conditions, components must be lightweight while being stress resistant and holding shape and size.

Medical devices: Safety and functionality for implants are critical micro precision is a necessity.

Electronics: Accurate metal stamping is vital for the assembly of smartphones, nagazettes, and circuit boards.

Concluding Remarks

In any context, performance means meeting a benchmark ascertained through measurable indicators; in this case, accuracy is an absolute prerequisite. Industries that rely on manufacturing stampings as components for the final product know very well that precision stampings guarantee safety, effectiveness, and quality. Modern manufacturers are exceeding expectations in CNC metal stamping, micro stamping, and advanced pressing technologies.

From automotive to aerospace, the demand for high precision parts will only escalate. It is critical to choose a vendor with profound expertise in tight tolerance stamping.