The Evolution of Bending Machines: From Manual to Fully Automated Systems

Introduction

Bending machines have played a crucial role in manufacturing, construction, and metalworking industries for decades. From simple manual devices to sophisticated, fully automated systems, the evolution of bending machines has significantly enhanced precision, efficiency, and productivity. This article explores the historical development, technological advancements, and future trends in bending machines.

Early Manual Bending Machines

According to a Bending Machines Market report, the industry is expected to grow significantly in the coming years.

In the early days, bending metal and other materials required manual force and basic tools. Traditional bending methods involved:

-

Hand-operated presses: Workers used manual force to shape metals.

-

Simple lever systems: These machines allowed for controlled bending but required significant human effort.

-

Mechanical brakes: Used in metal fabrication, mechanical brakes enabled more accurate bends but still required manual setup and operation.

Although effective, these early machines had limitations in precision, repeatability, and efficiency.

The Transition to Semi-Automated Systems

With industrialization and technological progress, semi-automated bending machines emerged, introducing improvements such as:

-

Hydraulic bending machines: These systems replaced manual force with hydraulic power, offering greater control and force consistency.

-

Pneumatic bending machines: Utilizing compressed air, these machines increased speed and reduced operator fatigue.

-

CNC (Computer Numerical Control) integration: The introduction of CNC technology in the late 20th century revolutionized bending accuracy, allowing for programmable bending sequences and repeatable operations.

Semi-automated systems reduced human intervention, improved production speed, and enhanced consistency in bending operations.

The Rise of Fully Automated Bending Machines

The development of fully automated bending machines marked a new era in manufacturing. These advanced systems feature:

-

Robotic integration: Industrial robots work alongside bending machines to automate material handling and bending processes.

-

AI-driven optimization: Artificial intelligence improves efficiency by analyzing data and adjusting bending parameters in real time.

-

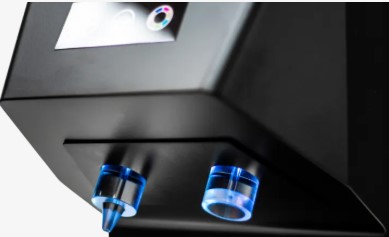

Laser and sensor-based precision: Modern bending machines use sensors and laser measurement technology to ensure precise and defect-free bends.

-

Multi-axis bending capabilities: Fully automated machines can execute complex bends in multiple directions without repositioning the workpiece.

Benefits of Fully Automated Bending Machines

-

Increased Precision and Accuracy: Automated machines eliminate human errors and achieve precise bends consistently.

-

Higher Productivity: Faster cycle times and reduced setup requirements lead to greater production efficiency.

-

Lower Labor Costs: Automation minimizes the need for manual intervention, reducing workforce expenses.

-

Enhanced Safety: Robotics and AI reduce the risk of workplace injuries associated with manual bending tasks.

-

Scalability and Customization: Automated bending systems can adapt to diverse production needs and material types.

Future Trends in Bending Machines

-

Smart Manufacturing Integration: IoT-enabled bending machines will communicate with other smart factory systems for real-time monitoring and predictive maintenance.

-

Eco-Friendly Innovations: Energy-efficient bending machines will contribute to sustainable manufacturing.

-

3D Bending Technology: Advances in 3D bending will enable more complex and customized part production.

-

Machine Learning Adaptation: AI-driven bending systems will continuously improve efficiency based on historical data and real-time analysis.

Conclusion

The evolution of bending machines from manual to fully automated systems has transformed the manufacturing landscape. As technology continues to advance, bending machines will become even more intelligent, efficient, and environmentally friendly. Companies that embrace these innovations will gain a competitive edge in precision manufacturing and industrial automation.