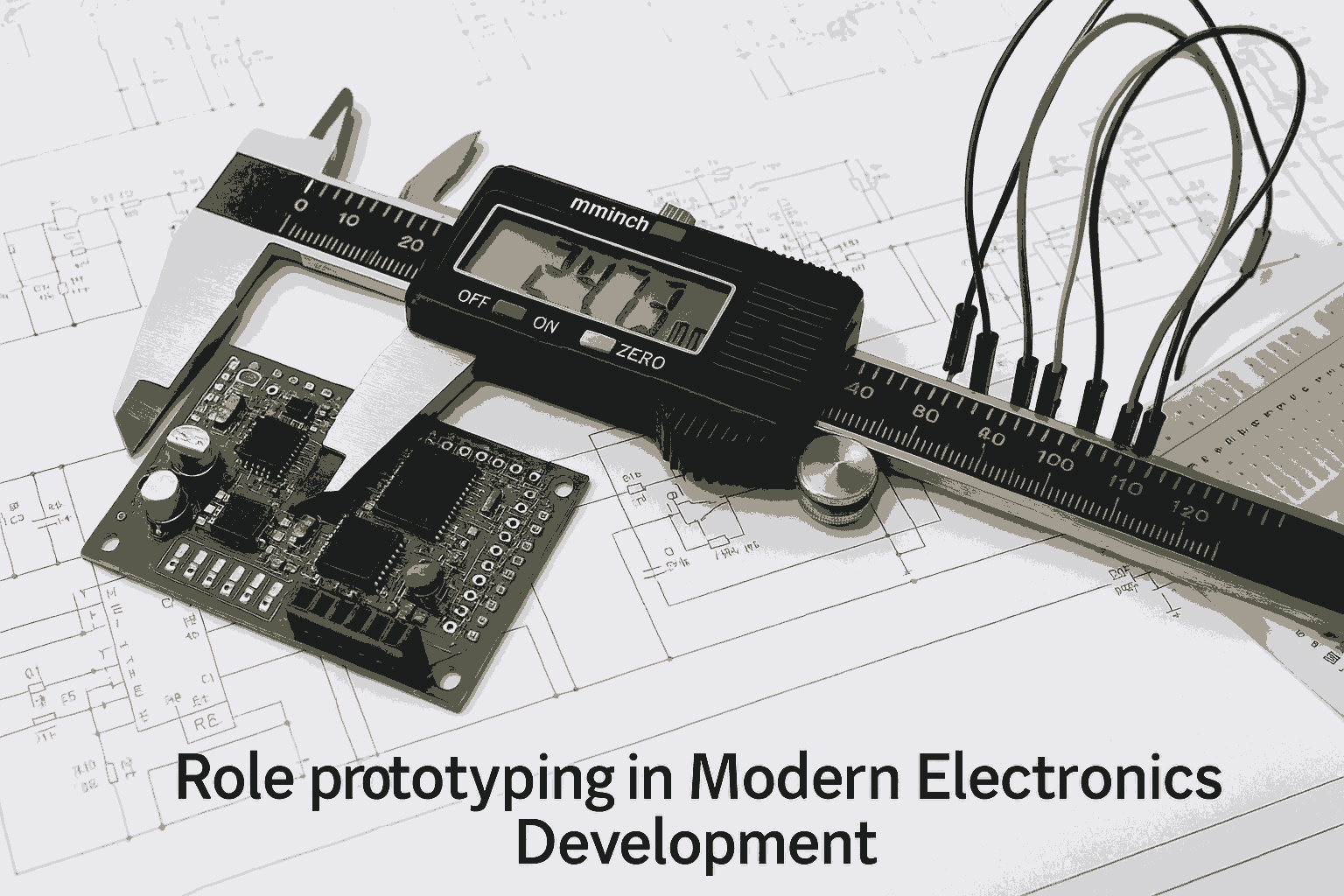

In today’s fast-paced electronics industry, bringing a product from concept to market requires speed, accuracy, and innovation. One of the most crucial steps in this process is prototyping. It bridges the gap between an idea and a fully functional device, helping teams validate designs, identify flaws, and reduce development costs.

Prototyping in modern electronics development is no longer optional—it’s essential for staying competitive.

Why Prototyping Matters

Prototyping allows engineers and product designers to convert theoretical concepts into tangible forms. These early models are critical for evaluating the functionality, feasibility, and performance of a product before mass production. It ensures that the end product meets technical specifications, user expectations, and compliance standards.

Accelerating Time-to-Market

Speed is a decisive factor in electronics. A robust prototyping process helps:

- Shorten development cycles

- Uncover design flaws early

- Iterate rapidly based on feedback

- Reduce trial-and-error in final manufacturing

This not only cuts down lead times but also gives companies a competitive edge by launching products faster.

Testing Real-World Functionality

Theoretical models often behave differently in real-world conditions. A prototype enables:

- Thermal, electrical, and mechanical testing

- Analysis of usability and ergonomics

- Verification of circuit performance

- Detection of interference or connectivity issues

By identifying and fixing problems during the prototyping phase, companies avoid expensive post-production changes.

Enhancing Collaboration Across Teams

Prototyping enhances communication among design, engineering, manufacturing, and quality teams. It provides a physical model that all stakeholders can interact with, allowing for:

- Better alignment on technical details

- Easier discussion of improvements

- Streamlined decision-making

- Shared understanding of product goals

This cross-functional collaboration leads to better, more refined final products.

Reducing Development Costs

While prototyping incurs upfront costs, it leads to savings in the long run by:

- Preventing design errors from reaching production

- Minimizing rework and component wastage

- Helping secure early feedback from clients or end-users

- Allowing cost optimization in material and layout choices

In high-stakes industries like medical electronics, automotive systems, and industrial control, early validation is critical for both safety and savings.

Conclusion: From Concept to Market-Ready

Modern electronics demand precision and agility. Prototyping plays a central role in transforming raw ideas into reliable products. It minimizes risks, accelerates development, and lays the foundation for scalable manufacturing.

Looking to bring your electronics project to life with expert prototyping support?

Explore InYantra’s rapid prototyping and product development capabilities today.