India’s Trusted Source for Cranio-Maxillofacial and Orthopedic Implants

India’s medical manufacturing sector has taken tremendous strides in recent years. In the domain of orthopedic and cranio-maxillofacial (CMF) implants, the country is now recognized globally for its quality, innovation, and affordability. Whether it’s for bone fixation or facial reconstruction, a reliable orthopedic implant company plays a critical role in patient outcomes. At the forefront of this industry is Aceosteo, a pioneering force counted among the top manufacturers of cranio-maxillofacial implants in India. With a commitment to precision and safety, companies like AceOsteo are setting new benchmarks in surgical support devices.

Understanding Orthopedic and Cranio-Maxillofacial Implants

Orthopedic implant companies are medical devices designed to replace or support damaged bones and joints, commonly used in trauma care, orthopedic correction, and post-tumor reconstruction. These include plates, rods, screws, and prosthetics crafted for durability and compatibility with the human body. In contrast, cranio-maxillofacial implants focus on restoring facial bones affected by trauma, deformities, or surgical removals. They are vital in procedures such as skull reconstruction, mandible support, and orbital repairs.

These two domains may serve different anatomical regions, but they share one goal—restoring quality of life with safe, effective, and high-performance implantable solutions.

Why India Is a Global Hub for Medical Implants

India’s rapid emergence as a medical device powerhouse isn’t accidental. It’s the result of years of investment in technology, infrastructure, and skilled labor. Today, the Top Manufacturers Of Cranio-Maxillofacial Implants India have global footprints, exporting to hospitals and surgical centers across Europe, Africa, the Middle East, and Southeast Asia.

Beyond affordability, what truly sets India apart is its ability to deliver consistent quality backed by ISO, CE, and Indian Medical Device Rules (IMDR) certifications. With world-class cleanroom facilities and precision machining, these companies manufacture implants that match—and often exceed—international standards.

Aceosteo—Redefining Standards in Implant Innovation

Among the standout names in the Indian medical device sector, Aceosteo has become synonymous with reliability and cutting-edge innovation. As a leading orthopedic implant company, AceOsteo manufactures a wide array of CMF and orthopedic solutions, including titanium facial plates, orbital meshes, fixation screws, and mandible reconstruction kits.

What makes AceOsteo distinct is not just its product range, but its integrated design and development approach. By combining surgeon feedback, real-world clinical data, and in-house R&D, the company delivers implants that are both clinically effective and surgically efficient.

How Precision Engineering Powers Quality Implants

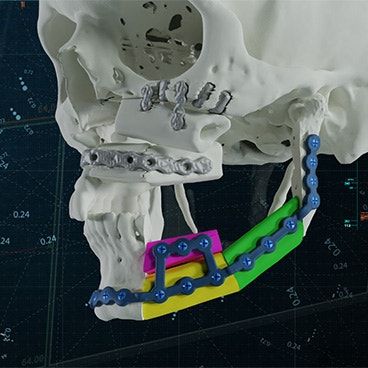

The quality of a medical implant begins at the design table. Indian manufacturers rely on modern tools like CAD/CAM systems, CNC machines, and 3D printing to ensure each product meets precise anatomical and mechanical requirements. These technologies allow for consistency across batches, customization for unique patient cases, and faster time-to-market for new innovations.

Companies like AceOsteo use these technologies to maintain tight tolerances, ergonomic contours, and smooth surface finishes—all essential for promoting faster healing and minimizing surgical complications.

Materials That Matter: Why Titanium Leads the Way

Material selection is central to implant performance. Titanium and its alloys have become the gold standard for both orthopedic and CMF implants due to their strength, lightweight nature, and superior biocompatibility. Additionally, titanium resists corrosion and integrates well with bone, reducing the chances of rejection or long-term complications.

AceOsteo sources medical-grade titanium from certified global suppliers and tests every batch for purity, composition, and structural integrity before fabrication. This rigorous material selection ensures the final implants are safe, strong, and stable within the body.

Customization and Patient-Specific Solutions

Every face, bone structure, and injury is different—so it’s no surprise that custom implants are revolutionizing modern surgery. Advanced tools like 3D modeling and virtual surgical planning now allow manufacturers to design implants tailored to an individual patient’s anatomy. These patient-specific implants offer a perfect fit, reduce surgery time, and improve outcomes dramatically.

Aceosteo is a leader in this field, providing 3D-printed CMF implants that are customized using CT scans and surgical inputs. The result? Smoother procedures, faster healing, and greater confidence for both surgeons and patients.

Strict Regulatory Compliance Ensures Safety and Trust

All top medical manufacturers in India must comply with IMDR guidelines, which include rigorous quality control, sterilization protocols, packaging validation, and batch traceability. These regulations ensure every implant is safe, traceable, and performs exactly as intended.

For international clients, companies like AceOsteo go a step further by acquiring CE and ISO 13485 certifications, making their implants suitable for use across the European Union, Middle East, and other regulated markets.

The Value Surgeons Receive Beyond the Product

Choosing an implant is not just about hardware—it’s about partnership. Leading Indian manufacturers support hospitals and surgical teams with training programs, demo kits, clinical trial data, and post-operative technical assistance. These services help build trust and ensure proper usage, especially for complex or new surgical techniques.

AceOsteo offers direct surgeon engagement programs, feedback integration systems, and rapid response teams that make them more than a supplier—they become part of the surgical team’s success.

Going Green: Sustainability in Implant Manufacturing

Modern implant manufacturers are increasingly adopting eco-friendly practices. From recycling metal scraps to using biodegradable packaging and installing solar-powered systems, companies are aligning their processes with global sustainability goals.

Aceosteo has taken active steps to reduce its environmental footprint without compromising quality. Through waste management systems and lean manufacturing, the company supports not only surgical health but also environmental health.

Why Global Hospitals Prefer Indian Implants

The growing demand for Indian-made CMF and orthopedic implants isn’t just due to affordability—it’s trust. Hospitals worldwide prefer Indian manufacturers because of their reliability, prompt supply chains, and adherence to international regulations.

Moreover, Indian companies are often more agile in meeting urgent demands or designing tailored solutions. This level of responsiveness and flexibility sets them apart from many larger but less adaptive players in the global market.

Medical Tourism and India’s Implant Advantage

India is also becoming a top destination for medical tourism, with thousands of international patients arriving each year for orthopedic, dental, and craniofacial surgeries. A key driver behind this boom is the availability of high-quality implants manufactured locally by trusted companies like Aceosteo.

Foreign patients benefit from reduced surgery costs, shorter waiting times, and the peace of mind that comes from knowing their implants are globally certified and trusted.

What’s Next for India’s Implant Industry?

As demand for advanced surgical solutions grows, Indian implant manufacturers are expanding their capabilities in the areas of:

- Smart implants with embedded sensors

- Bioresorbable materials for pediatric and trauma use

- AI-powered surgical planning tools

- Augmented reality (AR) and robotic-assisted procedures

Aceosteo, with its strong focus on innovation, is already researching next-generation implants that combine real-time data tracking with patient-specific healing patterns.

Conclusion

In today’s evolving healthcare landscape, precision, affordability, and innovation are non-negotiable. Indian implant companies, particularly Aceosteo, are successfully delivering on all three fronts. With world-class manufacturing, customized implant offerings, and deep clinical insight, they are not only serving patients but reshaping the global implant market.

For any hospital or healthcare provider looking to enhance surgical success, choosing a trusted orthopedic implant company from the Top Manufacturers Of Cranio-Maxillofacial Implants India is a strategic step toward quality and care.

Most asked question

- What are cranio-maxillofacial implants used for?

These implants are used for reconstructing facial bones in trauma, congenital conditions, or after tumor resection surgeries. - Are Indian-made implants safe for surgery?

Yes, Indian implants are safe and manufactured under strict compliance with IMDR, ISO, and CE regulations. - Why is titanium preferred in implant manufacturing?

Titanium is lightweight, strong, corrosion-resistant, and integrates well with bone, making it ideal for long-term use. - How does AceOsteo ensure implant quality?

AceOsteo uses certified raw materials, modern manufacturing, cleanrooms, and multiple quality control steps to ensure safety and durability. - Can implants be customized for individual patients?

Yes, many Indian manufacturers offer custom implants designed using 3D scans and advanced modeling for a perfect anatomical fit. - What support do surgeons get from implant manufacturers?

Manufacturers provide training, demo kits, technical guidance, and post-op assistance to ensure implant success in clinical use. - Are Indian implants exported globally?

Yes, Indian implants are exported to over 70 countries, trusted by hospitals and surgical teams worldwide for their performance and reliability. - What innovations are shaping the future of implants?

Future innovations include smart implants, biodegradable materials, AI-assisted design, and real-time performance monitoring.