When we think of the technologies that power modern life—cars, smartphones, medical equipment, aircraft—our attention often goes to the final products. But behind these marvels of engineering lies a world of tiny, intricate parts that make everything work flawlessly. These are precision turned components, and the experts who craft them—precision components manufacturers—are the real backbone of innovation.

What Do Precision Components Manufacturers Do?

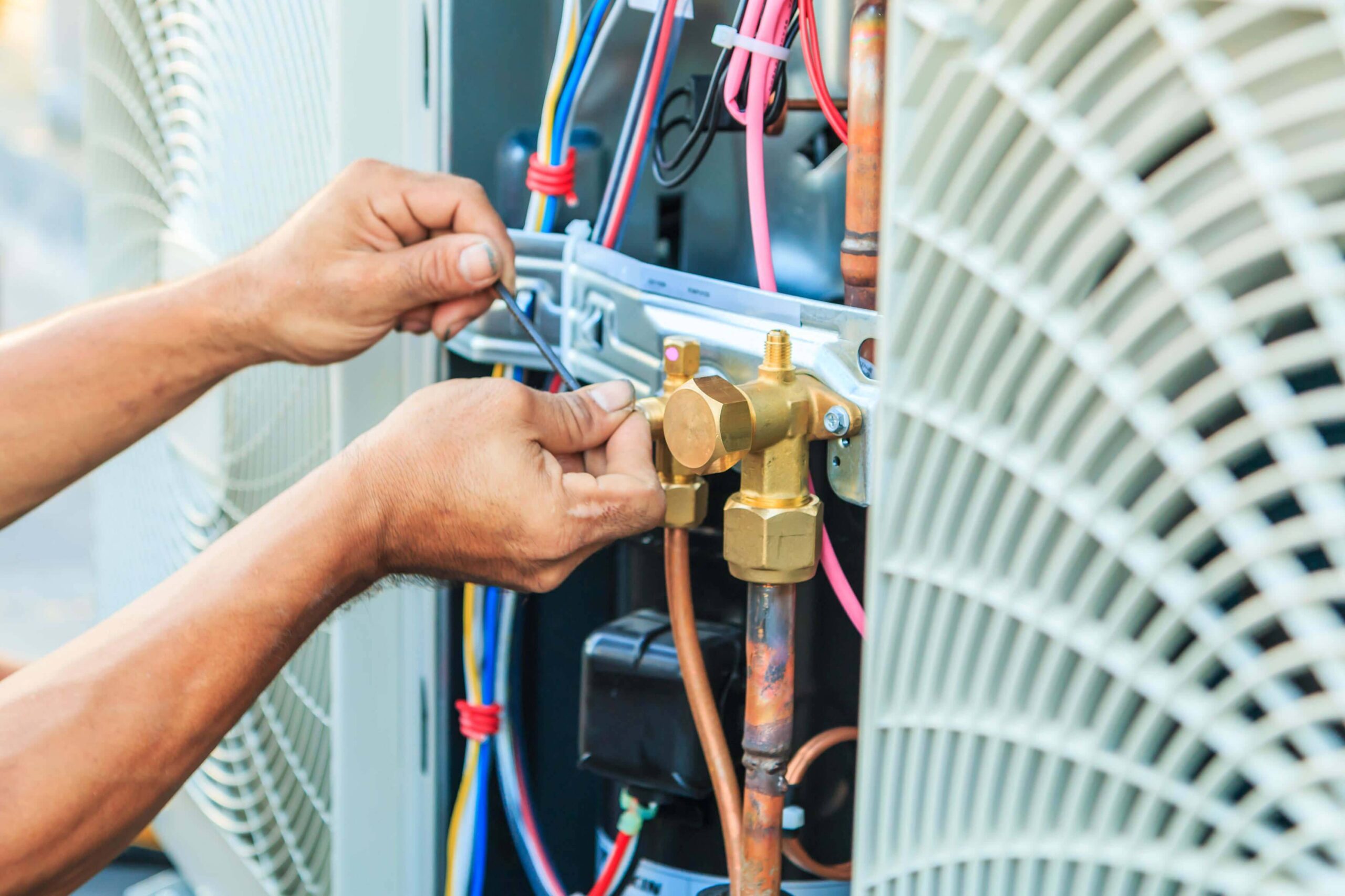

Precision components manufacturers specialize in creating finely machined parts that require exact measurements, tight tolerances, and flawless finishes. These components can range from complex automotive fittings to tiny medical device parts. The level of accuracy demanded in these industries leaves no room for error, which is why manufacturers in this space must combine high-end machinery, skilled technicians, and strict quality control measures.

Their job isn’t just to produce parts—it’s to deliver performance. A tiny flaw in a precision turned part could lead to system failure or safety issues, especially in industries like aerospace, defense, or healthcare. That’s why precision turned components manufacturers invest heavily in technology and process refinement.

Who Needs Precision Turned Components?

The need for precision goes beyond high-tech sectors. Any industry that relies on components with intricate geometries, threading, or specialized materials is likely sourcing from precision turned parts manufacturers. This includes:

- Automotive: Engine parts, fuel injectors, brake components

- Aerospace: Connectors, fasteners, sensor housings

- Electronics: Switchgear, terminals, adaptors

- Medical: Surgical tools, implant components, diagnostic devices

- Oil & Gas: Valve parts, pressure fittings, seals

Even something as simple as a water purifier may include turned parts that require micron-level accuracy. That’s why the demand for skilled precision turned components manufacturers continues to grow globally.

Quality Isn’t an Option—It’s a Requirement

One of the defining characteristics of a top-tier precision components manufacturer is an unwavering commitment to quality. This includes:

- Use of high-grade raw materials: Such as stainless steel, brass, titanium, or aluminum

- Advanced CNC and VMC machining: For superior surface finish and accuracy

- Stringent inspection protocols: Including digital measurement tools and quality audits

- Certifications: ISO 9001, IATF 16949, or RoHS compliance for global acceptability

For customers, this translates into reliability, long-term performance, and reduced maintenance costs. For industries, it means safety, efficiency, and a competitive edge.

The Human Side of Precision Manufacturing

Behind every component is a team of dedicated professionals—machine operators, quality analysts, designers, and engineers—working in harmony to produce excellence. Good precision turned parts manufacturers not only invest in machines but also in people. Skilled labor is essential for reading blueprints, fine-tuning machines, and ensuring consistency in every production batch.

Many manufacturers also offer custom solutions, working closely with clients to develop parts tailored to specific needs. This collaborative approach leads to innovation, better design integration, and stronger business relationships.

Why Choose an Experienced Manufacturer?

Selecting the right manufacturer can make or break your product. An experienced precision components manufacturer brings years of expertise, efficient processes, and a deep understanding of material behavior. They don’t just make parts—they solve problems, offer design input, and help streamline the product development cycle.

For startups and established enterprises alike, partnering with reliable precision turned components manufacturers can significantly cut down lead times and improve end-product performance.

“In a world that demands ever-smaller, smarter, and more efficient technologies, the role of precision turned components has never been more vital. These tiny parts are shaping the future—quietly but powerfully.

And as industries continue to evolve, the need for trustworthy partners like precision turned parts manufacturers will only grow. From raw material to finished part, their attention to detail ensures that everything else works smoothly.

Looking for more than just precision? A reliable coupling manufacturer in India can also be a great addition to your supply chain, offering strength and durability where connections matter most”.